Brick-shaped ceramic liner ZJCER-OS35

Classification:

Key words:

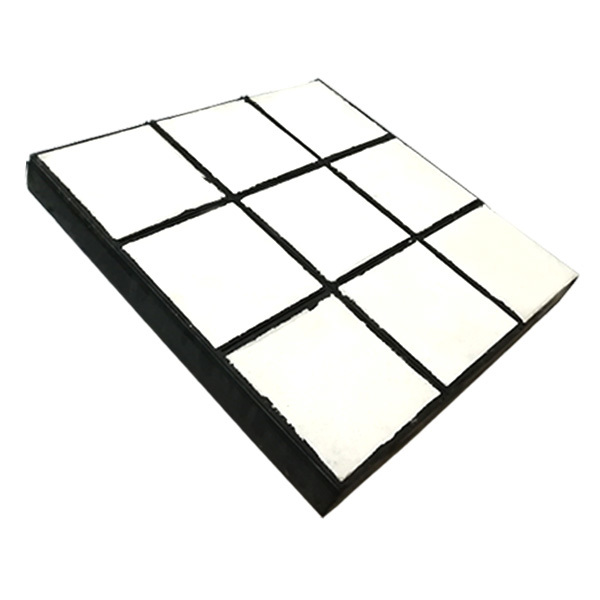

Brick-shaped ceramic liner ZJCER-OS35

Related Downloads

For more information, please contact us directly by phone or email

Product Details

Brand: Tianlihe

ZJCER-OS35 ceramic liner, specially designed for high wear and high impact working conditions. It has strong wear resistance, especially in the wear environment of high-speed operating materials. The rubber module absorbs impact energy, and the ceramic blocks (Al2O3) vulcanized on the rubber provide wear protection for the surface. The bottom steel plate is equipped with high-strength bolts, making installation simple and quick.

Ceramic liner product structure:

● 20mm ceramic (Al2O3) - wear-resistant;

● 10mm elastic rubber layer - absorbs impact loads;

● 5mm steel plate - easy to install;

Ceramic liner features:

1. The three-in-one wear-resistant ceramic liner adopts modular production and assembly, allowing for replacement in high wear areas;

2. Provides double-headed bolt fixation and weldable installation methods;

3. Special rubber thermal vulcanization process ensures that the ceramic blocks embedded in the rubber layer are firmly bonded and also serves as a cushioning layer to prevent ceramic block breakage;

4. The shape, size, and thickness of the ceramic blocks or liners can be customized according to your specific working conditions or applications.

Typical applications of ceramic liners:

Used as wear-resistant linings in equipment for conveying large materials in normal temperature environments, with severe wear and strong impact.

● Vibrating feeders, transfer chutes;

● Pipes, silos, bins, storage tanks;

● Large buckets, discharge hoppers, transfer stations, hydrocyclones, chutes.

Related Cases

Recommend Products

Product Series

Message feedback

We will arrange an after-sales specialist to contact you as soon as possible to help you find a product or solution that meets your needs and goals.