Constant Pressure Secondary Belt Cleaner

Classification:

Key words:

Related Downloads

For more information, please contact us directly by phone or email

Product Details

Abstracts:

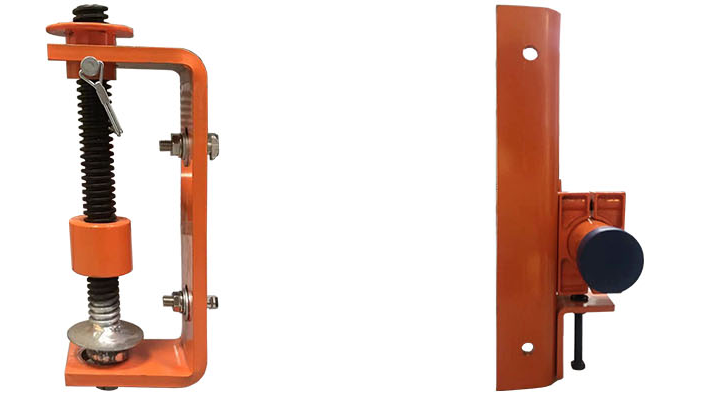

The use of pre-loaded pressure regulator (buffer spring group) can ensure a uniform and stable contact pressure between the scraper and the belt for a long time, and can be fine-tuned if necessary to ensure the scraping effect.

Description:

Secondary PU belt cleaner also named water Sweeper Cleaner, it usually be put behind the secondary tungsten cleaner to further to remove the most tiny and muddy material such as water and power.

Flat top and 85 Shore A PU material can softly touch to the belt bottom so that can clean the rest tiny material well. Adjustable tensioner part can make it very ersily to be modified as the conveyor frame.

|

Order No. |

Belt Width(mm) |

Blade Width(mm) |

Total Length(mm) |

|

ZJCLEAN-SC-650 |

B650 |

650 |

1650 |

|

ZJCLEAN-SC-800 |

B800 |

800 |

1800 |

|

ZJCLEAN-SC-1000 |

B1000 |

1000 |

2000 |

|

ZJCLEAN-SC-1200 |

B1200 |

1200 |

2200 |

|

ZJCLEAN-SC-1400 |

B1400 |

1400 |

2400 |

|

ZJCLEAN-SC-1600 |

B1600 |

1600 |

2600 |

|

ZJCLEAN-SC-1800 |

B1800 |

1800 |

2700 |

|

ZJCLEAN-SC-2000 |

B2000 |

2000 |

2900 |

|

ZJCLEAN-SC-2200 |

B2200 |

2200 |

3100 |

|

ZJCLEAN-SC-2400 |

B2400 |

2400 |

3300 |

Further Dimensions on Demand.

Advantage

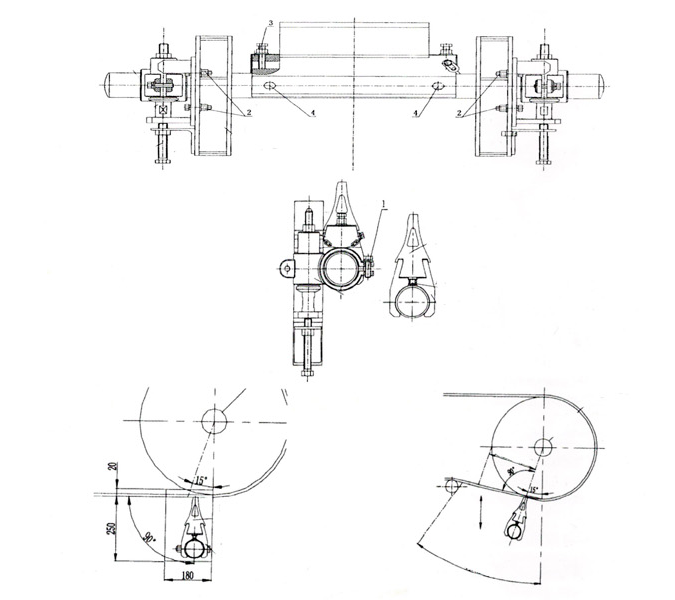

*The herringbone-shaped scraper has a hollow buffer hole, which has good followability to various belts. It can also use a reversible scraper for reversible belt conveyors.

*The scraper surface is integrated, and there is no dislocation between the pieces, and it is not easy to be stuck by foreign objects.

*The scraper and the fixed seat are combined with a dovetail groove, and there is a top tightening device to eliminate the clearance.

*Aluminum alloy knife holder, surface anodized, not easy to rust. It has a detachable fixed seat, which can be extracted from the side of the hopper, which is very easy to install or maintain.

*The pressure between the scraper and the belt can be adjusted by the pressure adjusting screw, which is simple, convenient and effective.

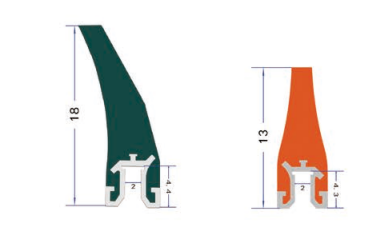

Blade Part:

This part touch conveyor belt bottom surface to clean the material on it.

*Wear abrasive Polyurethanes material.

*Color can be customized.

*Temperature from -20°C to 120°C available.

*Blade is detachable.

*Used in power plant, mining,port, cement plant.....

The second tensioner is 18(L) x 7(W) x 45(H)cm which is taller to matched the higher distance

between converyo frame and bottom belt. Larger adjustable range is convenient to operate. 2 bolts to install it on conveyor and 3 bolts fix it on cleaner tube.

Installation Drawing:

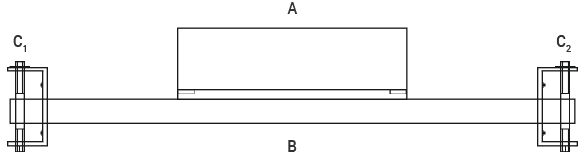

|

Belt Width(mm) |

A(mm) |

B(mm) |

C(pcs) |

Scraper Weight(KG) |

Total Weight(KG) |

|

650 |

650 |

1450 |

2 |

3.3 |

21.1 |

|

800 |

800 |

1650 |

2 |

5 |

24.4 |

|

1000 |

1000 |

1850 |

2 |

6.3 |

27.1 |

|

1200 |

1200 |

2050 |

2 |

7.6 |

30.4 |

|

1400 |

1400 |

2250 |

2 |

8.9 |

33.7 |

|

1600 |

1600 |

2450 |

2 |

10.2 |

37 |

|

1800 |

1800 |

2650 |

2 |

11.5 |

40.3 |

|

2000 |

2000 |

2850 |

2 |

12.8 |

43.6 |

|

2200 |

2200 |

3050 |

2 |

14.1 |

47 |

|

2400 |

2400 |

3250 |

2 |

15.4 |

50.3 |

Parameters:

Model Number: ZJCLEAN-SC

Belt Width: 650mm-2400mm

Material: PU

Belt Speed: Up to 1600 fpm (8 m/s)

Hardness: 85±2 Shore A

Temperature: Continuous:-30--70°C;Transient:-40--85°C/-40--120°C

Colour: Customised production

Elongation berak: 614

Deformation rate in 23h: 30

Springback(%): 20

Tensile strength: 53

Tear strength: 108

Abraion(mm3/1.61KM): 0.012

Corrosive Conditions: YES

Underground Applications: YES

Starting quantity: 1 Set

Warranty: 6 months

Supply capacity: 450 Set/ month

Certification:ISO9001;ISO14001;ISO45001;CE;UPEM

Packing: pallet, wooden case

Delivery Time:1~5 Set,1-3days / 10~20 Set,3-5days

FAQ:

1、How long will your rubber sheets last?

Each conveyor system transports different materials, so the friction coefficient generated can not be determined, you can tell me your requirements and transport materials, we help you to develop a solution.

2、How can I get some samples?

We will finish the samples within 3 days after you confirm our quotation and send us the sample fee. You can ask the courier company to pick up the samples from our company, or you can send us the collect account number of DHL, FedEx or UPS, we can send the samples to you through your account.

3、Can I visit your factory?

Yes, you are welcome to visit our factory anytime, we are near Henan Xinzheng Airport, only 15 minutes drive, we can arrange a car to pick you up.

Related Cases

Recommend Products

Product Series

Message feedback

We will arrange an after-sales specialist to contact you as soon as possible to help you find a product or solution that meets your needs and goals.