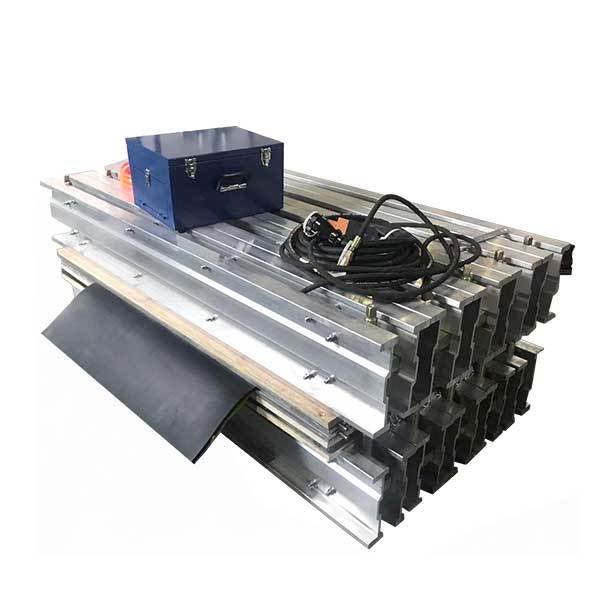

Heavy duty water cooled vulcanising machine

Classification:

Key words:

Related Downloads

For more information, please contact us directly by phone or email

Product Details

Brand: BAI-OTT

Model Number: ZJ-ROM

Belt Width: 650mm-2200mm

Heating Up Time: < 30min

Power: 9.8-36KW

Feature: Adjustable, Light and Portable

MOQ: 1 Set

Product Inspection:Available

Lead time:Ready to ship in stock

--------------------------------------------------------------------------------------------------

Description

The vulcanizing machine can perform on-site hot vulcanization joint processing for canvas, nylon, steel wire rope core, and whole-core flame-retardant conveyor belt. It is equipped with a light automatic electric control box, which is easy to operate and reliable.

The belt vulcanizer can perform on-site thermal vulcanization repair and joint treatment of canvas, nylon, steel wire rope core, and whole-core flame-retardant conveyor belts. It is equipped with a light-weight automatic electric control box. The connection between the electric control box and the host is made of integrated plug-ins and multi-cores. The cable is completed, the operation is convenient, and the work is reliable. It is powered by an ordinary three-phase power supply, the temperature of the hot plate is uniform, and the water pressure system supplies a uniform pressure (1.0~2.0mPa). Using ordinary tap water, the heating plate can be quickly cooled after the vulcanization is completed.

--------------------------------------------------------------------------------------------------

Including Parts:

Aluminum beam, Temperature control cabinet, Heat plate, Thermal baffle, Clamping nut screw, Spanner, Water press plate,Clamping bolts, Nuts, Gaskets, Auxiliary cable plug, Heavy duty hose, Eleectric pump, Hand manual pump.

--------------------------------------------------------------------------------------------------

Order No. Belt Width(mm) Size(mm) Heating Plate(mm) Power(kw)

ZJ-ROM-650 650 650*830 830*820 9.8

650*1000 1000*820 11.8

ZJ-ROM-800 800 800*830 830*995 11.97

800*1000 1000*995 14.4

ZJ-ROM-1000 1000 1000*830 830*1228 14.7

1000*1000 1000*1228 17.8

ZJ-ROM-1200 1200 1200*830 830*1431 17.2

1200*1000 1000*1431 20.7

ZJ-ROM-1400 1400 1400*830 830*1653 19.8

1400*1000 1000*1653 23.8

ZJ-ROM-1600 1600 1600*830 830*1867 22.3

1600*1000 1000*1867 27

ZJ-ROM-1800 1800 1800*830 830*2079 24.9

1800*1000 1000*2079 30

ZJ-ROM-2000 2000 1800*1000 830*2303 27.6

2000*1000 1000*2303 33.2

ZJ-ROM-2200 2200 2200*830 830*2478 29.7

2200*1000 1000*2478 35.8

Further dimensions on demand

--------------------------------------------------------------------------------------------------

Advantage

*Heating Plate: lightweight, portable, pressure and temperature uniformity;

*Water Plate: high pressure can reach Max. 2.0 MPa (20 bars or 290 psi);

*Cross Beam: lightweight & high tensile aluminum alloy;

--------------------------------------------------------------------------------------------------

Specifications

Technical Data

Pressure 2.0Mpa (200PSI)

Temperature 145℃

Surface Temperature ±3℃

Heating Up Time < 30min (normal temp up to 145℃)

Voltage 220V/380V/440V/660V, etc

Control Cabinet Power 9.8-36KW

Temp. Adjusting Range 0~200℃

Time Adjusting Range 0~99 min

--------------------------------------------------------------------------------------------------

Conveyor belt vulcanization joint operation process

1. Fix the conveyor joint part by F clamp.

2. Firstly peel off the cover rubber on the conveyor belt surface with pliers, then peel off the first layer of fabric with ply lifter and rubber knife, in the end, polish the splicing joint part with angle grinder and tungsten steel grinding disc.

3.Cleaning up the operation table, and lapping the wedge of the two heads. Apply the joint surface with hot splicing cement 2-3 times to ensure it fully penetrate into the connection gap in the wedge-shaped joint.

4. Laying unvulcanized core rubber and cover rubber on the joint.

5. Start vulcanizing process by the vulcanizing press machine. Press on vulcanizing plates, beams, tight the screws bolts. And then check the machine and control box, power. Then power on the machine and control the temperature up to 145 ℃。 After time up and hot splicing finished, dissemable the machine and remove all .

Related Cases

Recommend Products

Product Series

Message feedback

We will arrange an after-sales specialist to contact you as soon as possible to help you find a product or solution that meets your needs and goals.