Medium elastic polymer polyethylene cushioning rod

Classification:

Key words:

Related Downloads

For more information, please contact us directly by phone or email

Product Details

Abstracts:

BAI-OTT provides ZJ-IB impact bar for coal mine conveyor equipment, the steel fixing frame has excellent corrosion resistance in the high sulphur environment of coal mine.

Medium High Molecular Conveyor Bed is used in the blanking section of belt conveyor and is an alternative product of buffer supporting mixing. The main function is to better support and protect the conveyor belt, and reliably and effectively avoid the impact damage and splitting of falling materials on the conveyor belt.

Description:

The buffer strip is vulcanized from high molecular polyethylene plate and high elastic rubber. The high elastic rubber buffer bed absorbs the impact energy of falling materials on the conveyor belt and conveyor frame; The high-strength metal skeleton can withstand the impact of large load. The polymer polyethylene plate on the surface has high impact strength and low friction coefficient, which can reduce the friction with the conveyor belt and is conducive to the normal operation of the conveyor. The buffer sliding strip has flame retardant and antistatic properties and is suitable for combustible gas environment. The utility model has the advantages of compact structure, convenient installation and maintenance, long service life and no damage to the adhesive tape and mechanical joints. It is a kind of conveying auxiliary equipment composed of buffer strip and support frame. It is a good product instead of buffer roller. Installed under the conveyor belt, it can help absorb and decompose the impact force on the conveyor belt when the materials fall, prevent the material splash caused by uneven force on the belt, improve the stress condition of the conveyor belt and prolong the service life of the belt, It is an environment-friendly blanking buffer device.

|

Item |

Parameter |

Standard Type |

High Elastic Type |

Downhole Type |

|

|

UHMWPE Part |

Color |

Blue |

Blue |

Blue |

|

|

Tensile Breaking strength |

Mpa |

23 |

23 |

20 |

|

|

Elongation at break |

% |

300 |

300 |

250 |

|

|

Hardness |

Shore A |

60-70 |

60-70 |

65-75 |

|

|

Abrasion |

cm³ |

0.053 |

0.053 |

0.08 |

|

|

Density |

g/cm³ |

0.93-0.94 |

0.93-0.94 |

1.13 |

|

|

High Elastic Rubber Part |

Hardness |

Shore A |

60-65 |

45-50 |

60-65 |

|

Strength of Extension |

Mpa |

19 |

19 |

19 |

|

|

Elongation an break |

% |

400 |

400 |

400 |

|

|

Metal Part |

Type |

Aluminium Alloy |

|||

|

Bond Strength |

Bonding of PE&rubber |

N/mm |

≥10 |

≥10 |

≥10 |

|

Bonding of metal&rubber |

N/mm |

≥10 |

≥10 |

≥10 |

|

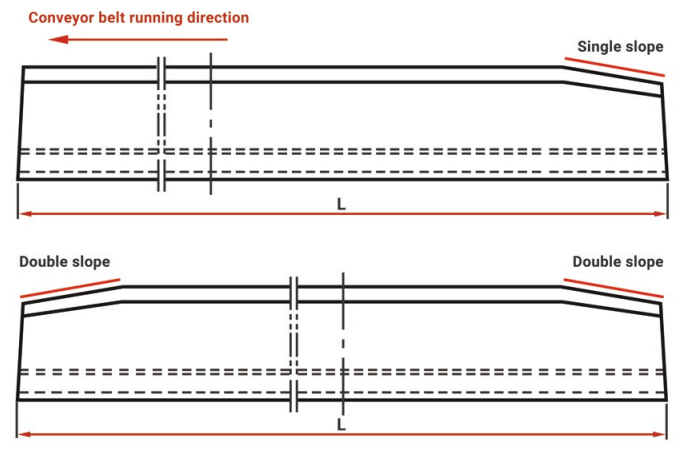

Shape of impact bar

Note: The single slope is directional and runs in the opposite direction to the conveyor belt, while a double slope is not directional.

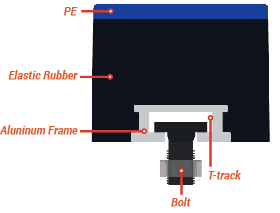

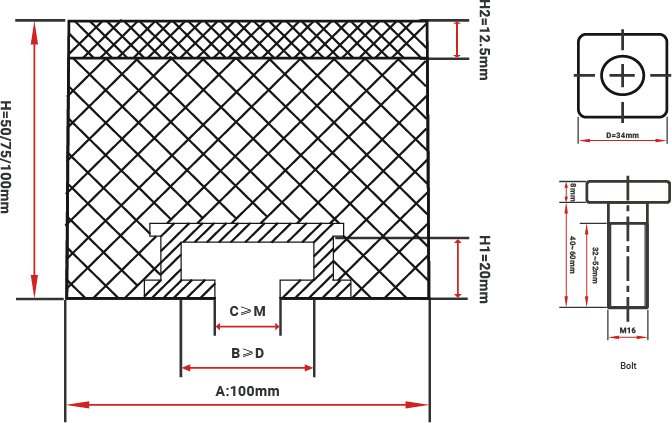

*PE mainly height in 12.5mm, high wear resistance, low friction coefficient and high impact toughness.

*The highly elastic rubber buffer layer absorbs the impact energy of falling materials on the conveyor belt.

*The high-strength metal frame can withstand large load impact without deformation.

*Steel bolts increase overall fastening.

*The”T-track” device makes the buffer strip have different fastening points in the whole length to ensure the connection is firm and reliable and easy to disassemble.

*The various parts are connected by hot vulcanizing technique.

Advantage

*Can withstand strong impact.

*Quick and simple installation, easy inspection and replacement.

*It is installed at the blanking point of the conveyor belt to prolong the service life of the belt.

*The surface contact between the buffer strip and the conveyor belt effectively prevents damage to the conveyor belt

*The conveyor belt is stressed evenly at the blanking port, which greatly reduces the daily repair and maintenance cost

Specifications

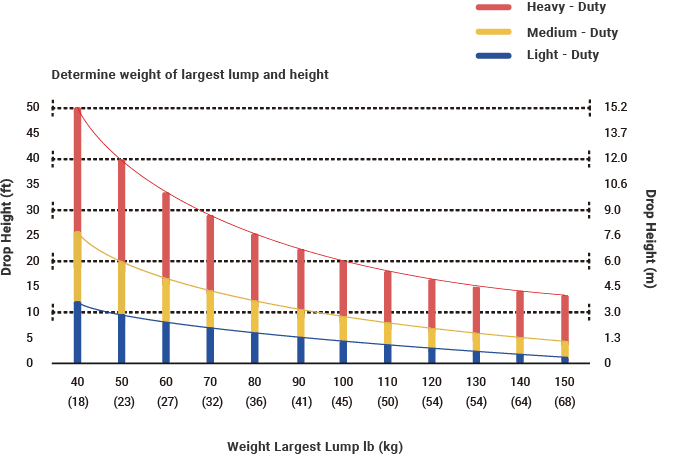

Factors affecting the use effect of Medium High Molecular Conveyor Bed:

1. Design of buffer bed and its impact resistance;

2. Quality of buffer strip;

3. Whether the material selection of polymer buffer bed support is reasonable and whether the welding is firm;

4. Whether the installation of buffer bed is applicable to the requirements of "triple buffer".

Parameters:

Model Number: ZJ-IB

Belt Width: 650mm-2400mm

Material: PE+Rubber+Steel Bolt

Belt Speed: Up to 1800 fpm (9 m/s)

Hardness: 60-70 Shore A

Temperature: Between -35 degrees F and 185 degrees F

Colour: Customised production

Corrosive Conditions: YES

Underground Applications: YES

Starting quantity: 1 Set

Warranty: 6 months

Supply capacity: 300 Set/ month

Certification: ISO9001; ISO14001; ISO45001; CE; UPEM

Packing: pallet, wooden case

Delivery Time:1~5 Set,1-3days / 10~20 Set,3-5days

FAQ:

1、How long will your rubber sheets last?

Each conveyor system transports different materials, so the friction coefficient generated can not be determined, you can tell me your requirements and transport materials, we help you to develop a solution.

2、How can I get some samples?

We will finish the samples within 3 days after you confirm our quotation and send us the sample fee. You can ask the courier company to pick up the samples from our company, or you can send us the collect account number of DHL, FedEx or UPS, we can send the samples to you through your account.

3、Can I visit your factory?

Yes, you are welcome to visit our factory anytime, we are near Henan Xinzheng Airport, only 15 minutes drive, we can arrange a car to pick you up.

Related Cases

Recommend Products

Product Series

Message feedback

We will arrange an after-sales specialist to contact you as soon as possible to help you find a product or solution that meets your needs and goals.