Ceramic Slide-Lag Pulley Lagging

Classification:

Product Alias:

Related Downloads

For more information, please contact us directly by phone or email

Product Details

And especially suitable for the muddy and damp difficult conveyor working environment because the ceramic is strong enough to protect the tiles and conveyor pulley. It is suitable forpulley lagging of long-distance and high-speed belt conveying equipment. It has good anti-slip ability, and prolongs equipment startup time by reducing the replacement frequency and replacement time of lagging.

Ceramic Cold Bonding Rubber Lagging (welding method)

The shell pulley lagging is composed of tile shell rubber plate and retainer. The retainer is welded on the drum and pressed against the tile shell rubber plate during installation. Tile shell rubber plate is made of wear-resistant rubber layer and metal layer by thermal vulcanization. According to different thickness, the tile shell rubber plate can be divided into 12mm, 15mm, 18mm and 20mm.

Coal washing plant, Cement plant, Metal factory, Metallurgical plant, Crusher like ceramic pulley lagging because their conveyor tile location in the damp places, the ceramic outstanding in high wear-resistant can better belt the conveyor running.

Product Features

1、Installation is more convenient and faster, and the replacement saves 50% of labor;

2、It will not hurt the non-working surface of the conveyor belt, which is more friendly to the conveyor belt;

3、Provide >30000 hours service life under normal working conditions;

4、Suitable for conveyor belt slippage, muddy, belt speed ≥ 3m/s, conveying capacity 1500t/h;

5、Safer hot vulcanization bonding process.

Advantages of Ceramic Rubber Sheet:

——The drum does not need to be disassembled;

——Quick and convenient maintenance and replacement;

——The adhesive layer is wear-resistant and has long service life;

——The product is suitable for rollers of various specifications;

Product Specification

|

Order No. |

Product Name |

Dimension(mm) |

|

ZJ-CRL-12 |

Weld on Pulley Lagging Sheet |

12*500*10000 |

|

ZJ-CRL-15 |

Weld on Pulley Lagging Sheet |

15*500*10000 |

|

ZJ-CRL-18 |

Weld on Pulley Lagging Sheet |

18*500*10000 |

|

ZJ-CRL-20 |

Weld on Pulley Lagging Sheet |

20*500*10000 |

|

Order No. |

Product Name |

Dimension(mm) |

|

ZJ-CRL-112 |

Flame Retardant Ceramic Lagging |

12*500*10000 |

|

ZJ-CRL-115 |

Flame Retardant Ceramic Lagging |

15*500*10000 |

|

ZJ-CRL-118 |

Flame Retardant Ceramic Lagging |

18*500*10000 |

|

ZJ-CRL-120 |

Flame Retardant Ceramic Lagging |

20*500*10000 |

Further dimensions on demand

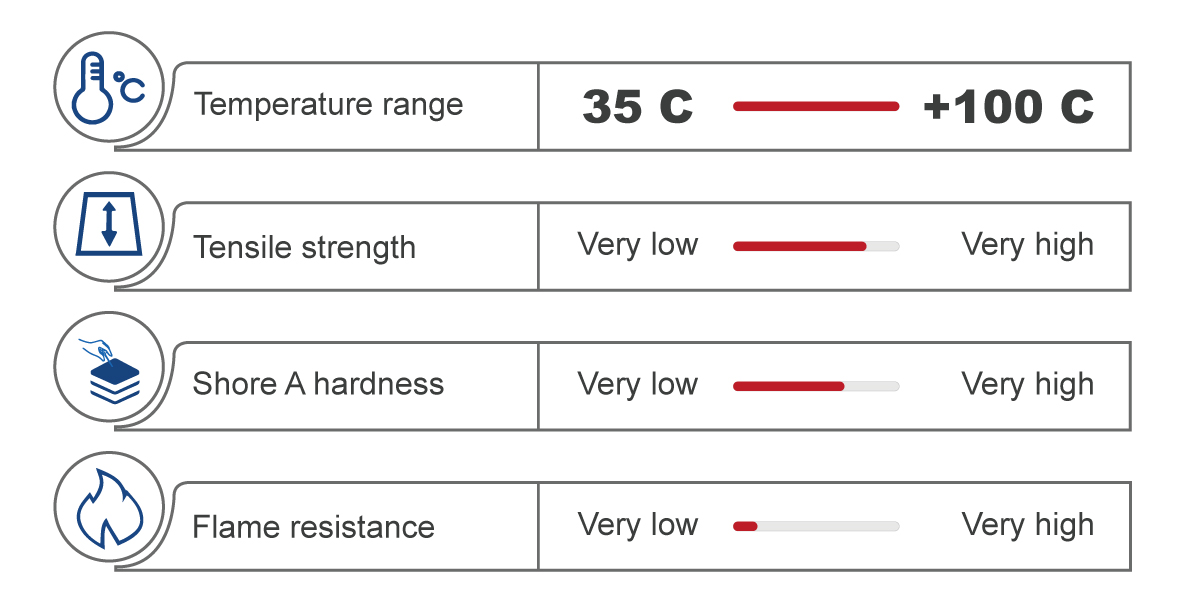

Parameters

| Material | Ceramic+Rubber |

|---|---|

| Model Number | ZJ-CRL |

| Thickness | 12mm,15mm,18mm,20mm |

| Colour | Black |

| Feature | Wear-Resistant and quick |

| Conveyor belt width | Variable |

| Installation | Head Drum and Tail Drum |

| CN Bonding | Available |

| Hardness |

65±5 Shore A |

| AL2O3 Content |

92%,95% |

| Volume Density | >3.5 g/cm³ |

| Tensile Strength | ≥18Mpa |

| Ceramic Size | 20*20*7mm |

| Tear elongation | 450% |

| Starting quantity | 10m² |

| Warranty | 24 months |

| Supply capacity | 8000m²/month |

| Certification | ISO9001;ISO14001;ISO45001;CE;UPEM |

| Packing | Pallet, wooden case |

| Delivery Time | 50~100m²,3-5days/200~500m²,7-10days |

FAQ

1、How long will your rubber sheets last?

Each conveyor system transports different materials, so the friction coefficient generated can not be determined, you can tell me your requirements and transport materials, we help you to develop a solution.

2、How can I get some samples?

We will finish the samples within 3 days after you confirm our quotation and send us the sample fee. You can ask the courier company to pick up the samples from our company, or you can send us the collect account number of DHL, FedEx or UPS, we can send the samples to you through your account.

3、Can I visit your factory?

Yes, you are welcome to visit our factory anytime, we are near Henan Xinzheng Airport, only 15 minutes drive, we

Related Cases

Recommend Products

undefined

Product Series

Message feedback

We will arrange an after-sales specialist to contact you as soon as possible to help you find a product or solution that meets your needs and goals.