Cold Adhesive SA3000

Classification:

Product Alias:

lagging

pulley

Bai-Ott

Related Downloads

For more information, please contact us directly by phone or email

Product Details

Cold vulcanizing splicing fluid SA3000 is widely acknowledged as one of the best cold vulcanizing splicing fluid. With distinguished splicing intensity exceeding German industry-standard DIN and equal to the hot splicing intensity, the SA3000 plays an irreplaceable part in conveyor belt splicing jointing as well as cold seamless splicing. It is excellent properties far more exceed other similar products in the same industry over the world.

Vulcanizing splicing fluid SA3000 fit for lacing between rubber and rubber, rubber and metal. It is an ideal adhesive for cold vulcanization lacing, repair, pulley lagging and all kinds of rubber gasket materials.

Usage: Must be mixed with Hardener30008 in a ratio of 4%(40g hardener with 1kg fluid)

Advantage

——Safe due to flame-resistance,also suiltable for underground and overground project.

——Ordinary tools can work well, no need for large equipment such as vulcanizing machines.

——After emergency repair, work starts immediately, reducing machine halt loss to a minimum level.

METHODS

OF USE

- SA3000

STEP 1

STEP 1

Draw a marking ling 2-3 cm outside the in jured area. Use a grinder to polish the damaged area until there is

no bulge in the damaged area.

STEP 2

STEP 2

Use Cleaning Solvent SA3500 to deeply clean the polished surface and wait for it to dry.

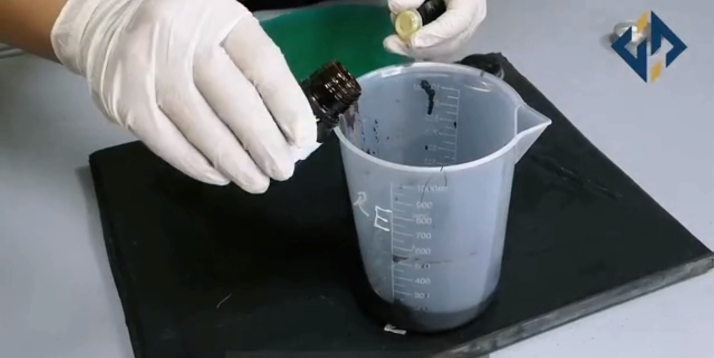

STEP 3

STEP 3

Mix SA3000A and SA3000B in a ratio of 100:4.

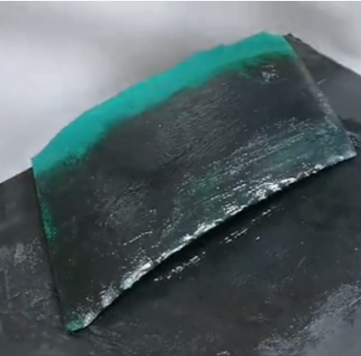

STEP 4

STEP 4

Apply SA3000 twice to the damaged surface and once to the repair strip.

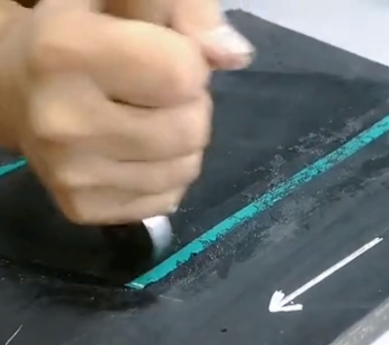

STEP 5

STEP 5

Use a flat roller to compact the repair strip.

STEP 6

STEP 6

After the repair is completed, apply the mixed liquidon the edge to allow the CN layer on the edge of the

repair strip to be naturally

Caution

Caution

If damaged needs a few of repair strips, look out the lap way. We can operate as image shows.

This product is suitable for repairing conveyor belt splices, conveyor belt end splices, pulley lagging, etc. It is the same as the SC2000.

Specifications

|

Order No. |

Description |

Color |

Weight |

Package |

|

SA3000 |

SA3000 Splicing Fluid |

Black |

1kg |

10tins/ carton |

|

SA3000T |

SA3000 Splicing Fluid |

Black |

260kg |

Barrel |

|

SA3000B |

Hardener |

Purple |

40g |

10 bottles/ box |

NOTE: QUANTITY LARGER(MORE THAN 500KGS), OEM CAN BE ACCEPTABLE.

Quality Certifications

Novelty Product Features

Wear resistance, Standard grade, Aging resistance, High strength, High impact resistance, High temperature resistance, Flame retardant grade.

| SPECIFICATION: | ||

| PEEL STRENGTH/(N/2.5CM) | 20min | 95 |

| 2h≥ | 150 | |

| 48≥ | 195 | |

Technical Data

| Performance | Parameter |

| Item | Cold Vulcanizing Fluid SA3000 |

| Color | Black |

| Specific Gravity / 20°C | 1.45g/cm³ |

| Viscosity | 3200-3800mPa.s |

| Flame retardant | Flammable |

| Package | 1kg+40g |

| Besmear brushs area | 300g/m³ |

Attention

- The temperature of the construction enviroment and materials should be within 10°C-45°C

- Contruction surfaces should be dry and clean without any oil or chemical

- You should keep the rest SA3000 glue in bottle with seal cover and stay in dry and cool places

- Don't touch the sticky surface by your skin before curing, please wash your skin with soap as your unintentionally touch it

- Better have a trail sticking in your local construction site

Parameters

| Brand | BAI-OTT or OEM |

| Model | SA3000 |

| Colour | Black |

| Weight | 1KG&260KG |

| Fracture | Non flammable |

| Underground Applications | YES |

| Function | Conveyor belt cold bonding |

| Quality | Top-quality |

| Advantage | High Bonding |

| Usage | Pre-treatment of conveyor metal surface and rubber bonding |

| Type | Cold adhesive glue |

| Product Inspection | Available |

| Lead time | Ready to ship in stock |

| MOQ | 10 cans |

| Shelf life | 24 Months |

| Supply capacity | 6000 cans/ month |

| Certification | ISO9001; ISO14001; ISO45001; CE; UPEM |

| Packing | Pallet, wooden case |

| Delivery Time | 10~300 cans, 1-3 days / 500~1000 cans, 3-5 days |

FAQ

1、How long will your rubber sheets last?

Each conveyor system transports different materials, so the friction coefficient generated can not be determined, you can tell me your requirements and transport materials, we help you to develop a solution.

2、How can I get some samples?

We will finish the samples within 3 days after you confirm our quotation and send us the sample fee. You can ask the courier company to pick up the samples from our company, or you can send us the collect account number of DHL, FedEx or UPS, we can send the samples to you through your account.

3、Can I visit your factory?

Yes, you are welcome to visit our factory anytime, we are near Henan Xinzheng Airport, only 15 minutes drive, we can arrange a car to pick you up.

Related Cases

Recommend Products

undefined

Product Series

Message feedback

We will arrange an after-sales specialist to contact you as soon as possible to help you find a product or solution that meets your needs and goals.