Diamond Cold Bonded Rubber Sheet (welding method)

Classification:

Product Alias:

Related Downloads

For more information, please contact us directly by phone or email

Product Details

PRODUCT PARAMETERS

Advantages of Diamond Rubber sheet

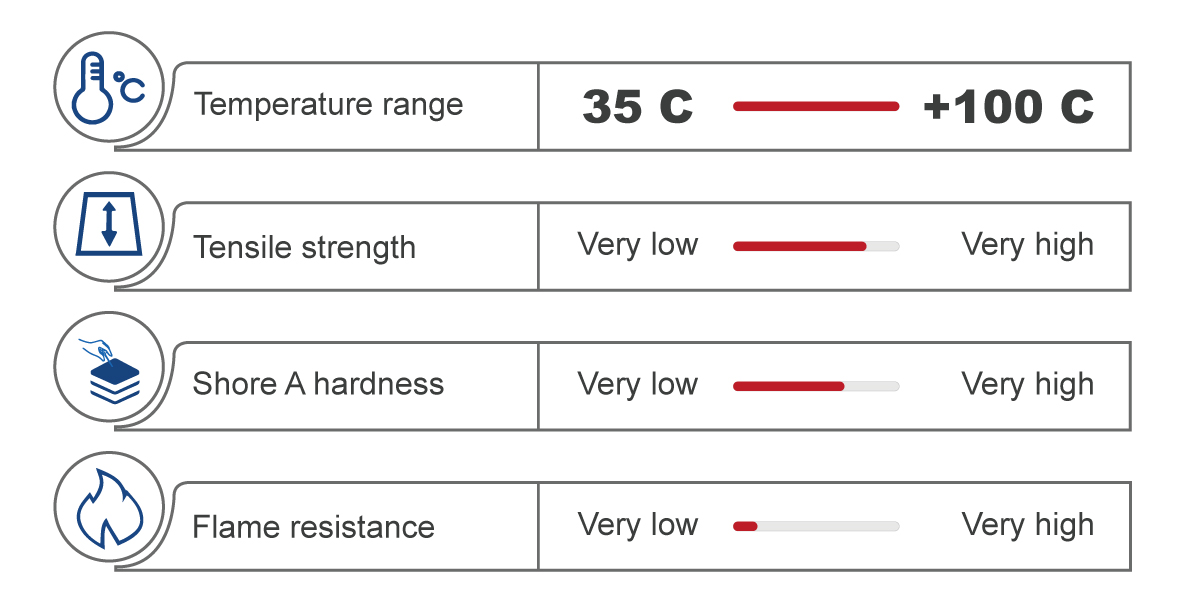

——Wear resistance: It is made of high elasticity and high wear-resistant rubber raw materials;

——Friction: Diamond groove and z-groove assist the belt to operate, and the friction and traction force are doubled;

——Heat dissipation: The groove and the gap between the insert plates can play a good effect on heat dissipation and reduce the degree of friction heat;

——Adaptability: Meet the needs of cold resistance ,high temperature resistance, anti-static, anti flame retardant, non-toxic and other index requirements;

——Customized: Customized according to the drum size of different specifications and models to meet the needs of each diameter and length of drum;

——Low cost: reduce downtime, improve efficiency and reduce use cost;

——Easy installation: special strip welding, safe and stable, easy to operate;

——Fast maintenance: the drum does not need to be disassembled, installed on site and replaced at any time;

——Long service life: high-quality rubber raw materials, wear-resistant and antistatic, and longer service life;

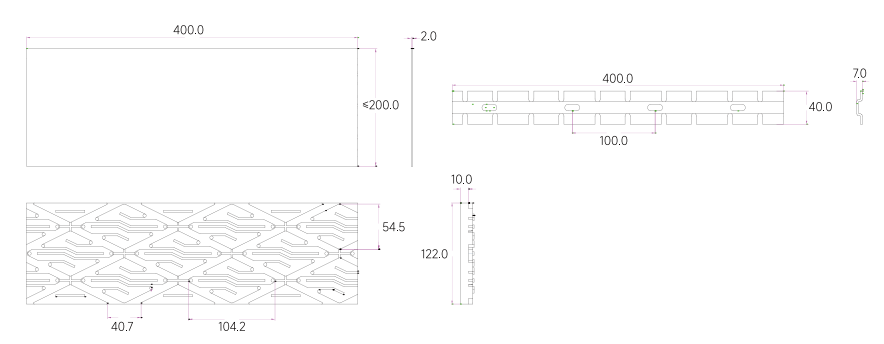

Product Specification

|

Order No. |

Product Name |

Dimension(mm) |

|

ZJ-MRL-15 |

Weld On Pulley Lagging |

15*500*10000 |

|

ZJ-MRL-20 |

Weld On Pulley Lagging |

20*500*10000 |

Specifications

|

Raw Material |

Steel+Rubber |

|

Model |

ZJ-MRL |

|

Hardness |

60±5 shore A |

|

Conveyor belt width |

Variable |

|

Pulley Diameter |

≥300mm |

|

Installation Method |

On-site |

|

Feature |

Wear-Resistant |

|

Color |

Black |

|

CN Bonding |

Available |

|

Thickness |

10/12/15/20mm |

|

Starting quantity |

20m² |

|

Warranty |

24 months |

|

Supply capacity |

8000m²/month |

|

Certification |

ISO9001;ISO14001;ISO45001;CE;UPEM |

|

Packing |

Pallet, wooden case |

|

Delivery Time |

50~100m²,3-5days/200~500m²,7-10days |

FAQ

1、How long will your rubber sheets last?

Each conveyor system transports different materials, so the friction coefficient generated can not be determined, you can tell me your requirements and transport materials, we help you to develop a solution.

2、How can I get some samples?

We will finish the samples within 3 days after you confirm our quotation and send us the sample fee. You can ask the courier company to pick up the samples from our company, or you can send us the collect account number of DHL, FedEx or UPS, we can send the samples to you through your account.

3、Can I visit your factory?

Yes, you are welcome to visit our factory anytime, we are near Henan Xinzheng Airport, only 15 minutes drive, we can arrange a car to pick you up.

Related Cases

Recommend Products

undefined

Product Series

Message feedback

We will arrange an after-sales specialist to contact you as soon as possible to help you find a product or solution that meets your needs and goals.