Heat Resistant Ceramic AI203 Belt Cleaner

Classification:

Product Alias:

ceramic

Bai-Ott

pulley

Related Downloads

For more information, please contact us directly by phone or email

Product Details

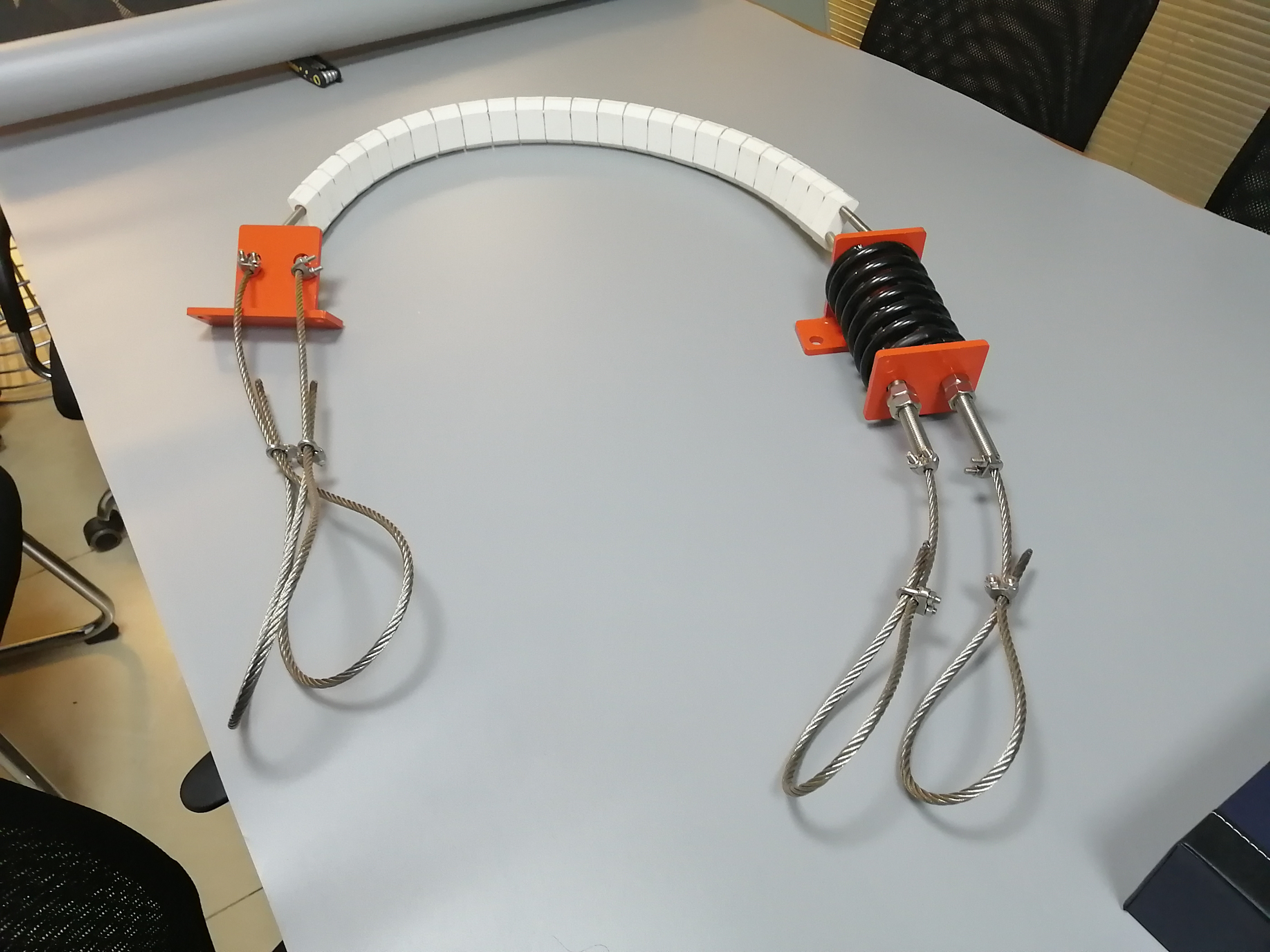

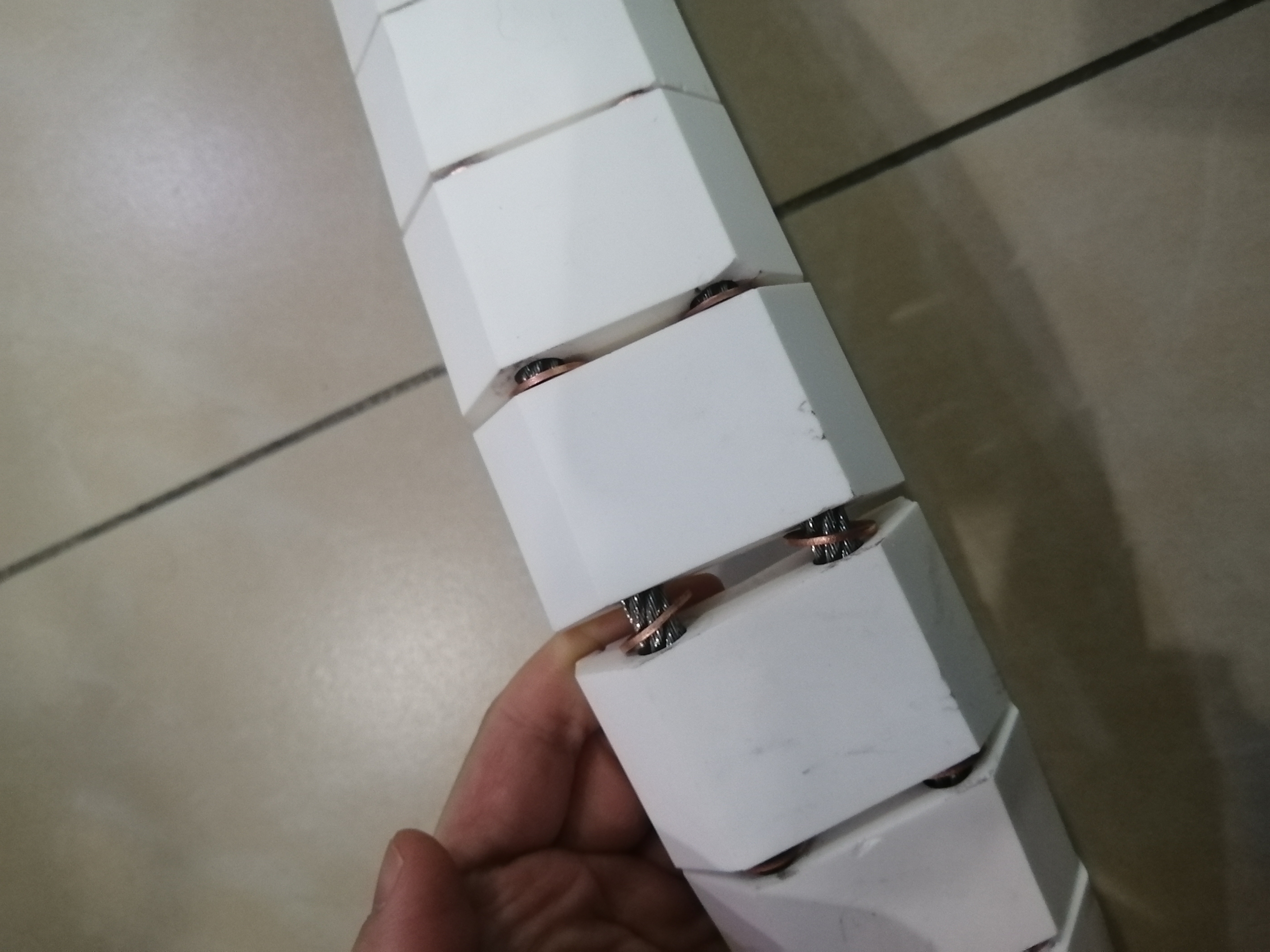

The ZJCLEAN-CA cleaner is composed of high quality wear-resistant ceramics, where hardness and abrasion resistance are indicators of the product's ability to be tested. The ceramic, composed of aluminium oxide (92%), reaches 9 on the Mohs scale of hardness.

The ZJCLEAN-CA has a simple design and is easy to install and maintain. It is suitable for iron ore, limestone, coal, quarry, clay, fertiliser and dusty high temperature materials.

Product Specification

|

Order No. |

Belt Width(mm) |

Weight(kg) |

Ceramic Blocks(pcs) |

Steel Length(m) |

|

ZJCLEAN-CA-650 |

650 |

9 |

20 |

2.8 |

|

ZJCLEAN-CA-800 |

800 |

9.5 |

25 |

3 |

|

ZJCLEAN-CA-1000 |

1000 |

10 |

30 |

3.2 |

|

ZJCLEAN-CA-1200 |

1200 |

10.5 |

35 |

3.4 |

|

ZJCLEAN-CA-1400 |

1400 |

11 |

41 |

3.6 |

|

ZJCLEAN-CA-1600 |

1600 |

11.5 |

46 |

3.8 |

|

ZJCLEAN-CA-1800 |

1800 |

12 |

50 |

4 |

|

ZJCLEAN-CA-2000 |

2000 |

12.5 |

55 |

4.2 |

|

ZJCLEAN-CA-2200 |

2200 |

13 |

61 |

4.4 |

|

ZJCLEAN-CA-2400 |

2400 |

13.5 |

67 |

4.6 |

More customised sizes on request

Advantage

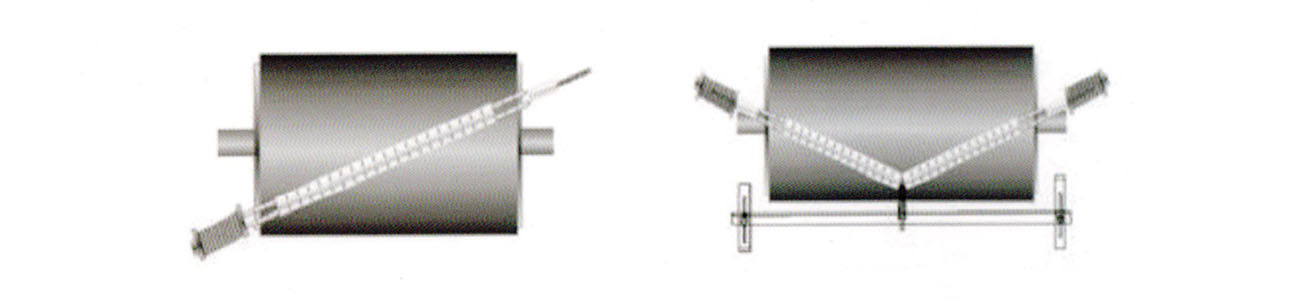

——Mounts at the head drum, achieving a cleaning performance efficiency level of up to 90% removal of all carryback within the material flow.

——Reduces conveyor mistracking and structural damage potential.

——Improves productivity levels.

——The surface of the ceramic cleaner is smooth and wears little to the belt, which greatly improves the life of the main auxiliary equipment of the belt conveyor, such as belts, drums and idlers, reduces the labor workload of the post personnel, reduces the production cost and improves the production efficiency.

——The ceramic belt cleaner is installed obliquely on the roller part, and will be closely attached to the belt conveyor to form point contact, which is particularly effective for conveying wet and sticky materials, which is incomparable to the scraper cleaner.

——The ceramic belt cleaner can be installed on belt conveyors in various working environments. It only takes about half an hour to install, and it is easy to maintain.

Conveyor belt cleaning solutions for most situations

*High-speed conveyor line

*Difficult to clean up muddy bulk

*High temperature conveyor line

*Scraper replacement hassle

*Blade wears too fast

*Frequent adjustment of locking is time-consuming and labor-intensive

Porduct features

*Can be adapted to various high-speed working conditions.

*It can adapt to the high temperature working conditions of steel industries and cement industries

*Using highly wear-resistant ceramics, the service life of the Belt Scraper Blade and Belt cleaner is longer than that of other materials.

*Lower conveyor belt wear.

*Belt cleaner installation and daily maintenance are simpler.

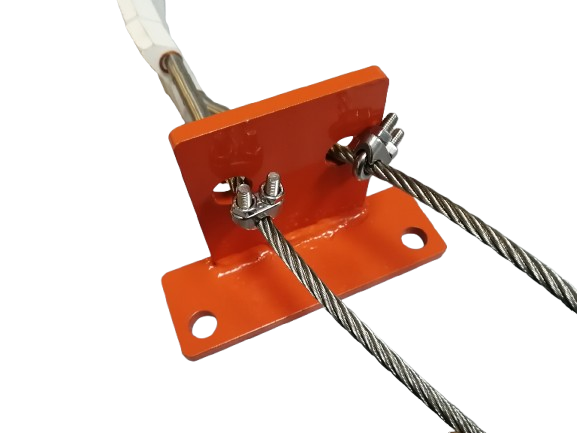

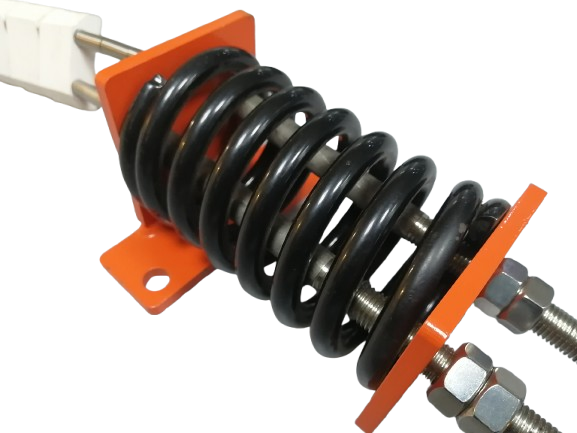

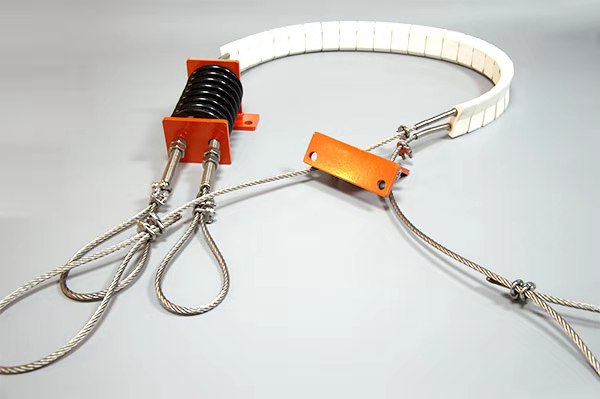

Spring tensioner

Bai-Ott ZJCLEAN-CA ceramic cleaner adopts spring tensioner at both ends, which can be more firmly affixed to the pulley surface, and the pressure is even without damaging the conveyor belt. Both ends are mounted with up and down tensioners, which can reduce the wear and tear on the ceramic block and also slide smoothly over the mechanical splicing part.

Quality Certifications

Parameters

| Brand | BAI-OTT or OEM |

| Model | ZJCLEAN-CA |

| Material | Alloy, Ceramic |

| Colour | White |

| Belt Width | 650mm-2400mm |

| AI2o3 | ≥92% |

| Belt Speed | Up to 1600 fpm(8m/s) |

| Mohs hardness | 9 Mohs |

| Water Absorpation | ≤0.02% |

| Fracture Toughness | 3.65mpa |

| Bending Strength | 255mpa |

| Density | ≥3.6g/cm³ |

| Compressive Strength | ≥850mpa |

| Thermal Conductivity | 16.8W/m.k |

| Corrosive Conditions | YES |

| Underground Applications | YES |

| Product Inspection | Available |

| Lead time | Ready to ship in stock |

| MOQ | 1 Units |

| Warranty | 6 Months |

| Supply capacity | 450 units/ month |

| Certification | ISO9001; ISO14001; ISO45001; CE; UPEM |

| Packing | Pallet, wooden case |

| Delivery Time | 1~5 units, 1-3 days / 10~20 units, 3-5 days |

FAQ

1、How long will your rubber sheets last?

Each conveyor system transports different materials, so the friction coefficient generated can not be determined, you can tell me your requirements and transport materials, we help you to develop a solution.

2、How can I get some samples?

We will finish the samples within 3 days after you confirm our quotation and send us the sample fee. You can ask the courier company to pick up the samples from our company, or you can send us the collect account number of DHL, FedEx or UPS, we can send the samples to you through your account.

3、Can I visit your factory?

Yes, you are welcome to visit our factory anytime, we are near Henan Xinzheng Airport, only 15 minutes drive, we can arrange a car to pick you up.

Related Cases

Recommend Products

undefined

Product Series

Message feedback

We will arrange an after-sales specialist to contact you as soon as possible to help you find a product or solution that meets your needs and goals.