Medium Fire-resistance Rubber Impact Slider Bed

Classification:

Product Alias:

Bai-Ott

Related Downloads

For more information, please contact us directly by phone or email

Product Details

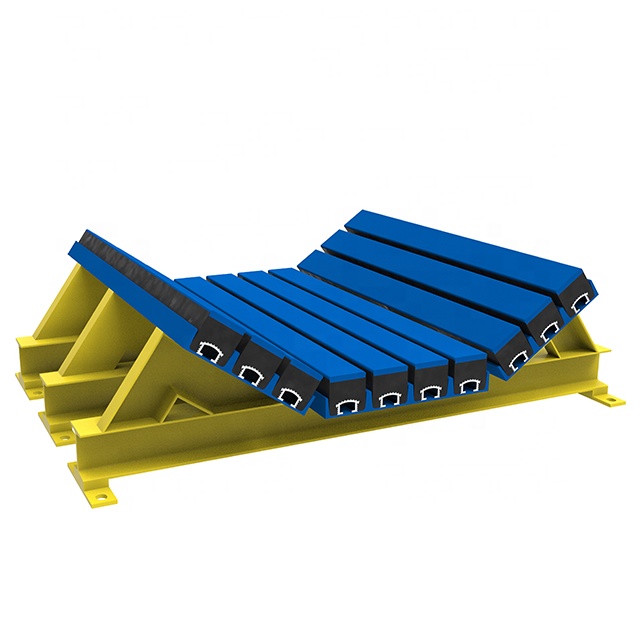

Medium Fire-resistance Impact Slider Bed is also known as flame retardant buffer sliding bed and flame retardant buffer supporting bed. The chute of the flame-retardant buffer bed is composed of flame-retardant buffer strips. The flame-retardant buffer strips are mainly made of excellent high elastic special rubber layer, which fully and effectively absorbs the impact force when the material falls, greatly reduces the impact on the conveyor belt when the material falls, and truly improves the stress condition of the falling point.

The special UHMW high molecular polyethylene surface is adopted to reduce the friction coefficient between the conveyor belt and the flame-retardant buffer strip sliding strip to a low level and has good wear resistance. The chute of the flame-retardant buffer bed uses the face-to-face contact of the conveyor belt, with uniform stress, which effectively prevents the longitudinal tear of the belt caused by the breakage and falling off of the idler, and greatly reduces the probability of longitudinal tear after the belt is penetrated by sharp tools or sharp materials. The effective support design of the buffer bed ensures that the buffer bed can meet the use demand of impact force.

Detailed Parameter

|

Item |

Parameter |

Standard Type |

High Elastic Type |

Downhole Type |

|

|

UHMWPE Part |

Color |

Blue |

Blue |

Blue |

|

|

Tensile Breaking strength |

Mpa |

23 |

23 |

20 |

|

|

Elongation at break |

% |

300 |

300 |

250 |

|

|

Hardness |

Shore A |

60-70 |

60-70 |

65-75 |

|

|

Abrasion |

cm³ |

0.053 |

0.053 |

0.08 |

|

|

Density |

g/cm³ |

0.93-0.94 |

0.93-0.94 |

1.13 |

|

|

High Elastic Rubber Part |

Hardness |

Shore A |

60-65 |

45-50 |

60-65 |

|

Strength of Extension |

Mpa |

19 |

19 |

19 |

|

|

Elongation an break |

% |

400 |

400 |

400 |

|

|

Metal Part |

Type |

Aluminium Alloy |

|||

|

Bond Strength |

Bonding of PE&rubber |

N/mm |

≥10 |

≥10 |

≥10 |

|

Bonding of metal&rubber |

N/mm |

≥10 |

≥10 |

≥10 |

|

Further Dimensions on Demand

| Recommended number of impact bars | |||||||||||

| Belt Width(mm) | 550 | 650 | 800 | 1000 | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 | 2400 |

| Number of bars | 4 | 6 | 7 | 10 | 10 | 13 | 15 | 16 | 18 | 19 | 21 |

Quality Certifications

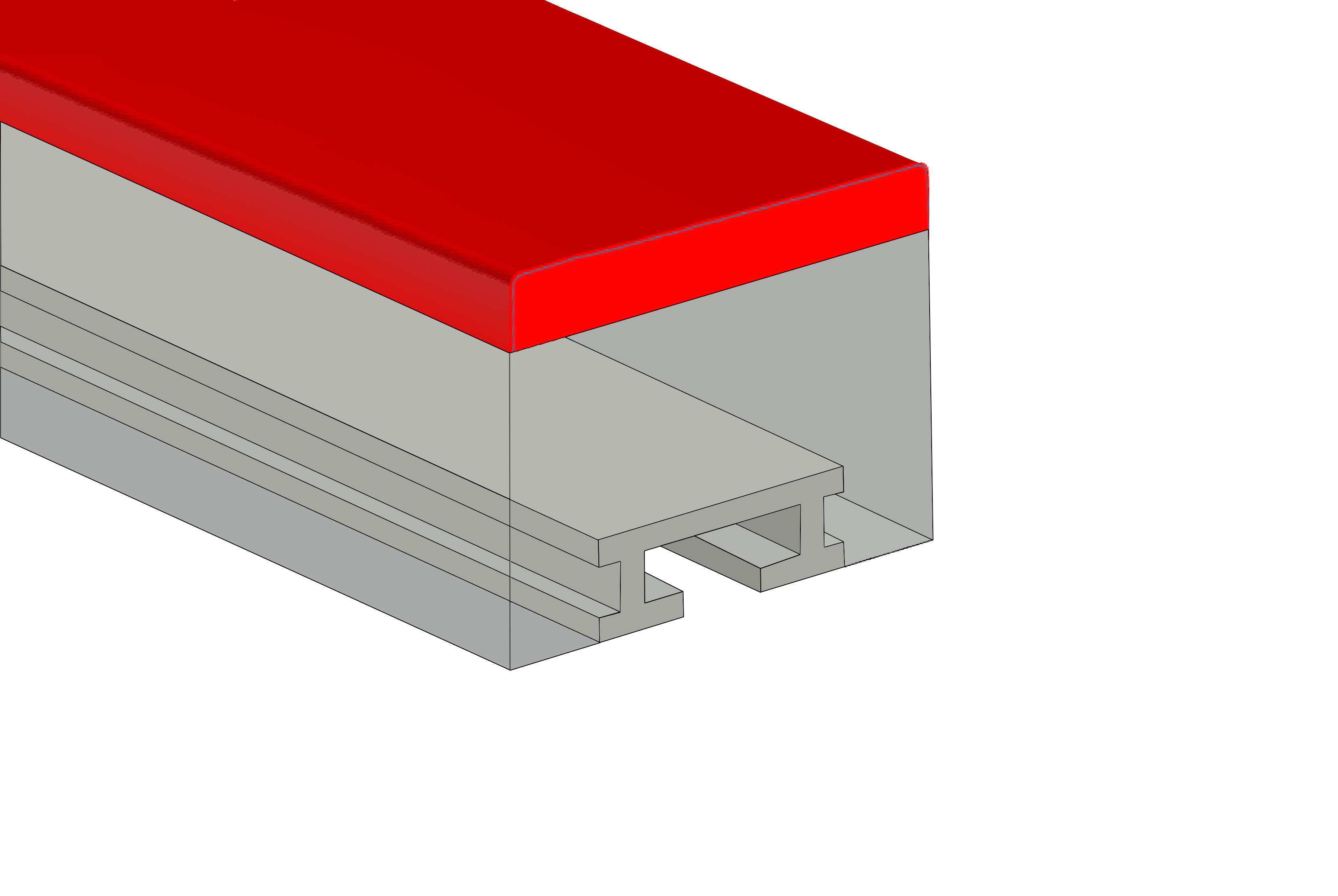

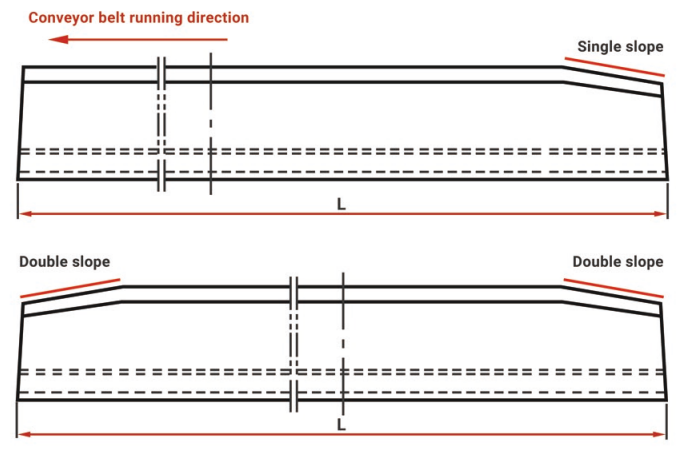

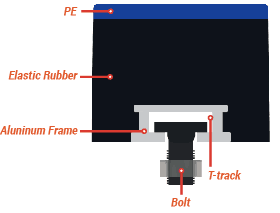

Shape of impact bar

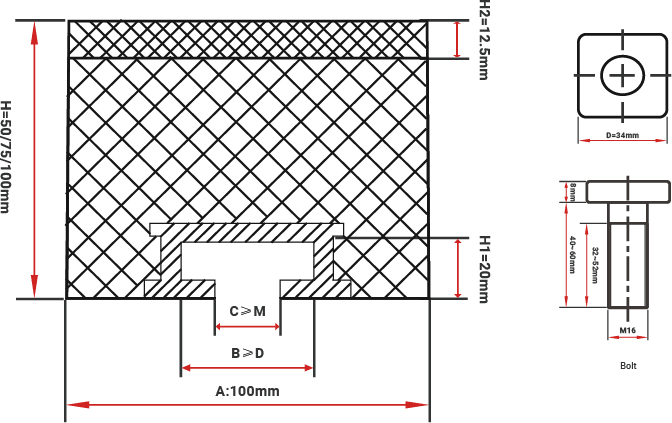

Note: The single slope is directional and runs in the opposite direction to the conveyor belt, while a double slope is not directional.

*PE mainly height in 12.5mm, high wear resistance, low friction coefficient and high impact toughness.

*The highly elastic rubber buffer layer absorbs the impact energy of falling materials on the conveyor belt.

*The high-strength metal frame can withstand large load impact without deformation.

*Steel bolts increase overall fastening.

*The”T-track” device makes the buffer strip have different fastening points in the whole length to ensure the connection is firm and reliable and easy to disassemble.

*The various parts are connected by hot vulcanizing technique.

Advantage

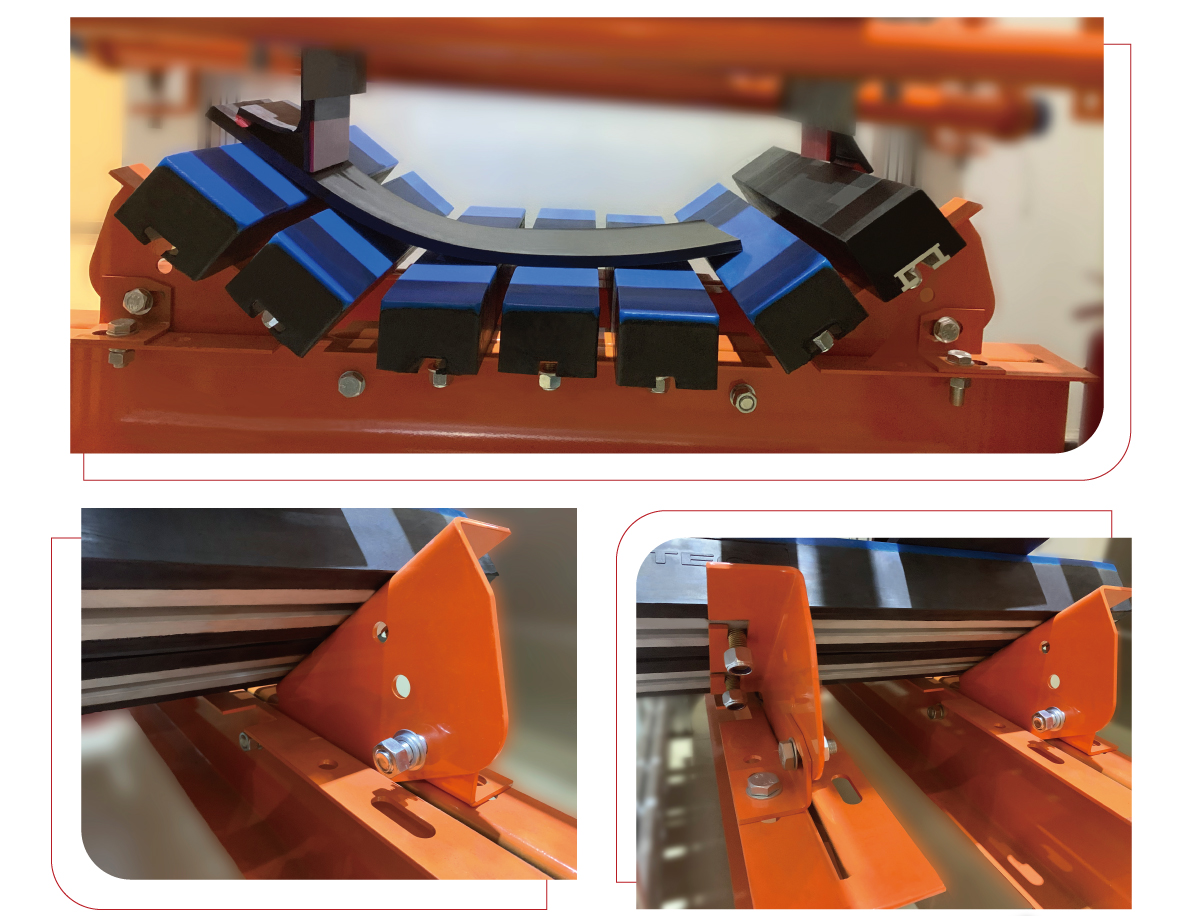

——The surface contact between the flame-retardant buffer strip and the sliding strip of the conveyor belt effectively prevents the damage to the conveyor belt

——The conveyor belt is stressed evenly at the blanking port, which greatly reduces the daily repair and maintenance cost

——Effectively eliminate material splash and leakage caused by uneven stressof conveyor belt

——The smooth surface of higher molecular weight polyethylene reduces the friction of the conveyor belt during operation

——The arc design on the surface of polyethylene layer makes the conveyor belt run smoothly

——The high elastic special rubber layer can absorb the impact force of materials to a great extent

——All parts of the flame-retardant buffer strip and sliding strip are connected by thermal vulcanization process, which is compact and firm

——The design of the bottom steel structure makes the disassembly and assembly convenient and fast

At present, our company's existing impact bars molds can process lengths of 1220mm, 1400mm, 1500mm,1524mm etc., and the width is between 100-300mm. Our daily output is about 150-200 pcs, which can basically meet the requirements of our customers.

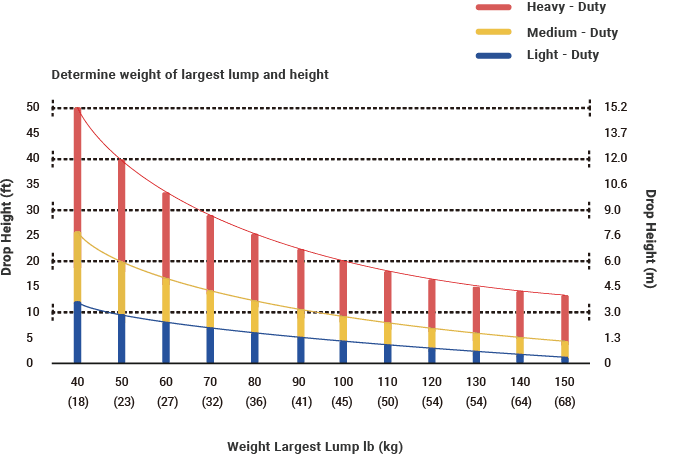

When materials strongly drop impact bed, rubber part mainly plays a good buffering role by the physical elasticity. Therefore, the rubber elasticity must up to certain level.

As international requirements, the rubber part of impact strip should be about Shore A 55° ( Mining usage must be treated flame retardant rubber), if the hardness is too high, it will be easy to break.

Besides, tear resistance, tensile strength, elongation at break, adhesion strength of rubber and metal profiles are also influence the service life of the products.

Elastic rubber is generally divided into three thicknesses of 50mm, 75mm and 100mm, and the width is 100mm. The choice of thickness is mainly determined by factors such as the impact force or the diameter of the drop materials during the operation.

The hot vulcanization is generally formed in a hot vulcanizing machine in one time. Heat the UHWMPE plate with the elastic rubber in a high temperature environment to make the surface molecules active. And then bond the wear abrasive plate and the elastic rubber effectively prevent tackless during operation and increase service life.

Parameters

| Brand | BAI-OTT or OEM |

| Model Number | ZJ-FRB |

| Material | PE+Rubber+Steel Bolt |

| Colour | Customised production |

| Belt Width | 550mm—2400mm |

| Belt Speed | Up to 1800 fpm (9m/s) |

| Hardness | 60—70 Shore A |

| Sample | Available |

| Application | Coal mines, Cement plants, Steel plants, Power plants and other factories |

| Facture | High elastic+Adjustable+High Wear-Resistant+High Quality |

| Corrosive Conditions | YES |

| Underground Applications | YSE |

| Product Inspection | Available |

| Lead time | Ready to ship in stock |

| MOQ | 10 Pcs |

| Shelf Life | 12 Months |

| Supply Capacity | ISO9001; ISO14001; ISO45001; CE; UPEM |

| Packing | Pallet, Wooden case |

| Delivery Time | 10~30 Pcs, 1-3days / 50~100Pcs, 3-5days |

FAQ

1、How long will your rubber sheets last?

Each conveyor system transports different materials, so the friction coefficient generated can not be determined, you can tell me your requirements and transport materials, we help you to develop a solution.

2、How can I get some samples?

We will finish the samples within 3 days after you confirm our quotation and send us the sample fee. You can ask the courier company to pick up the samples from our company, or you can send us the collect account number of DHL, FedEx or UPS, we can send the samples to you through your account.

3、Can I visit your factory?

Yes, you are welcome to visit our factory anytime, we are near Henan Xinzheng Airport, only 15 minutes drive, we can arrange a car to pick you up.

Related Cases

Recommend Products

undefined

Product Series

Message feedback

We will arrange an after-sales specialist to contact you as soon as possible to help you find a product or solution that meets your needs and goals.