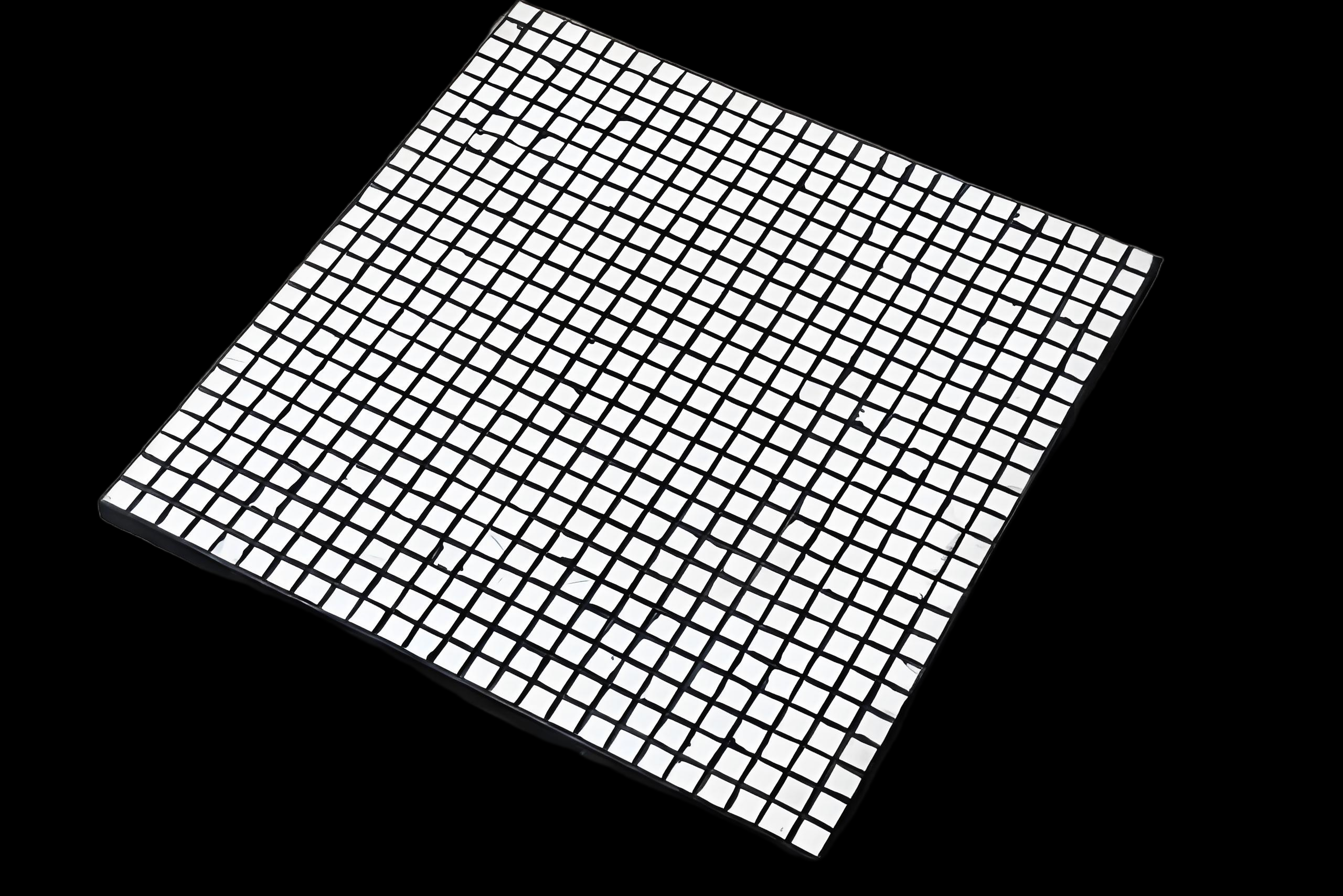

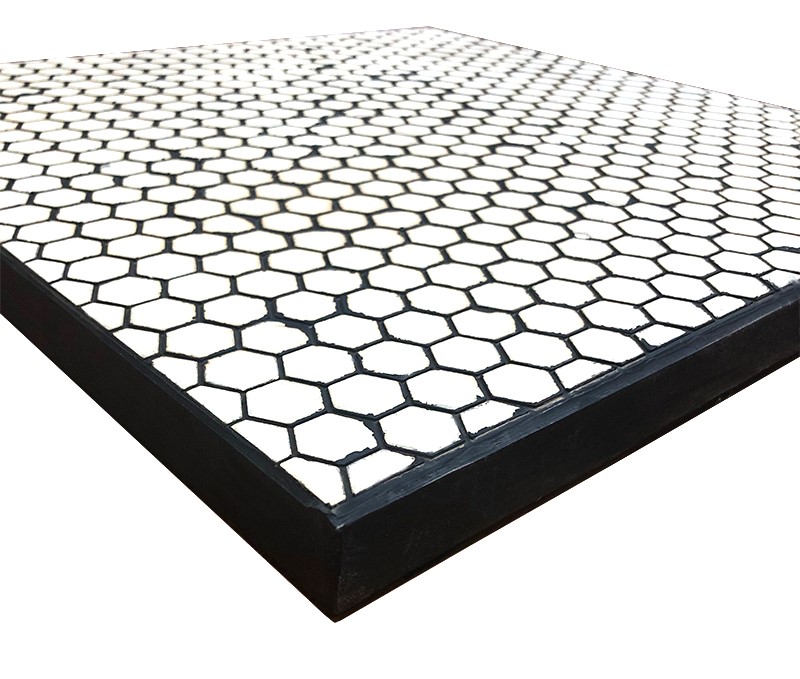

Hexagonal Wear-Resistant Ceramic Rubber Composite Liner Plate

Classification:

Product Alias:

Hexagonal Wear-Resistant Liner (Two-in-One)

ceramic

Bai-Ott

Related Downloads

For more information, please contact us directly by phone or email

Product Details

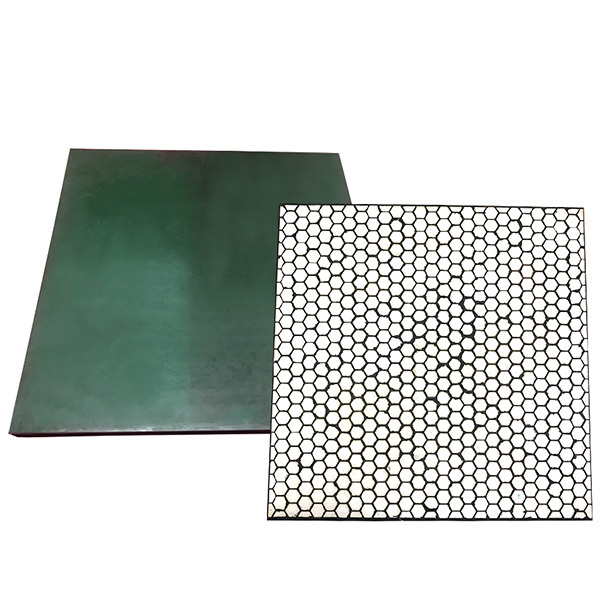

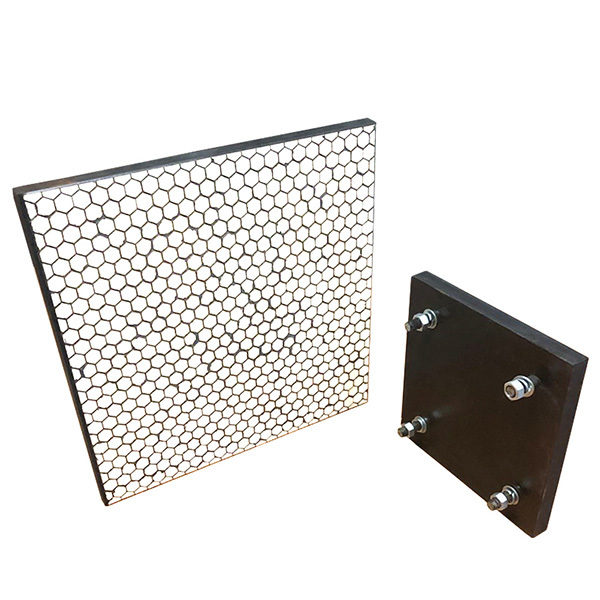

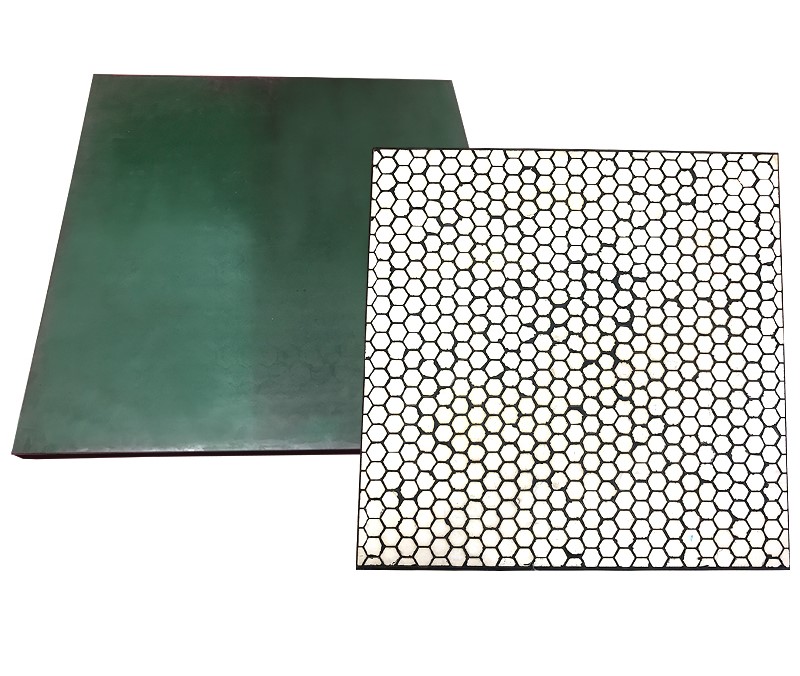

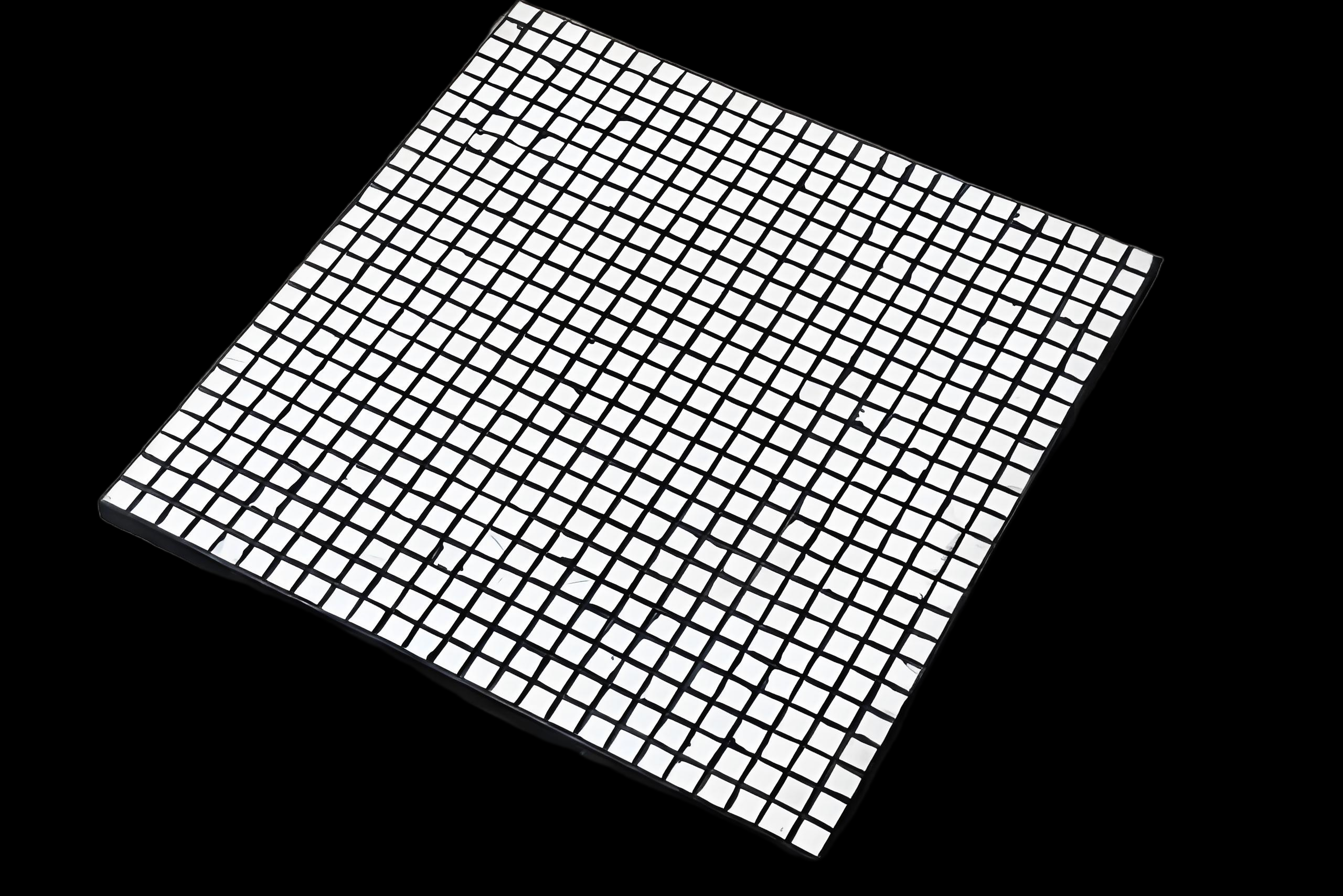

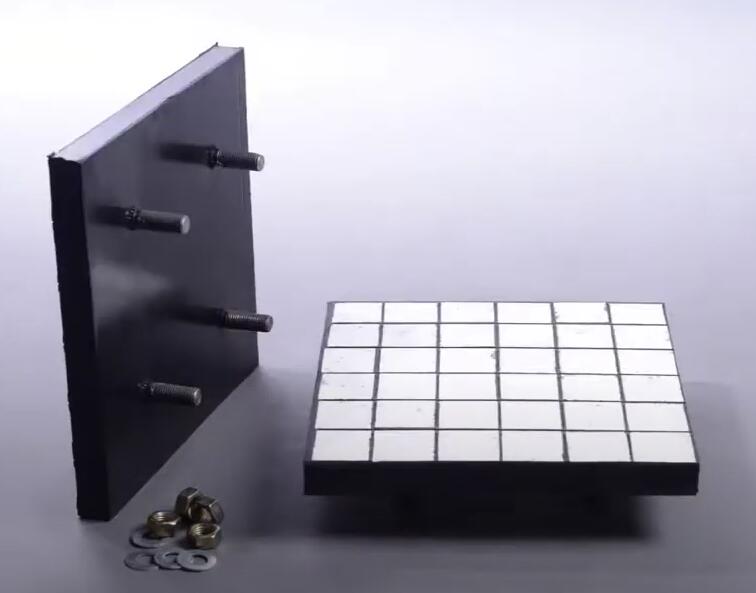

The rubber and ceramic composite wear-resistant products is to use the hot vulcanization process to vulcanize the toughened ceramic sheet in a steel plate groove equipped with special rubber, and the steel plate groove is equipped with countersunk bolts.Ceramic lining is divided into two-in-one liner and three-in-one liner.Two-in-one lining refers to the composite of ceramic and rubber.Three-in-one lining refers to the composite of ceramic, rubber and steel plate. And it comes with bolts for easy installation.

Structures of Ceramic Rubber Liner

Alumina Ceramic:

92% & 95% Ceramic, available with extensive sizes and shapes.

Rubber / PU Layer:

Superior compound rubber/polyurethane, impact-absorbing.

Connection:

Steel plate & studs, CN bonding layer, ect.

Excellent bonding:

Ceramic, rubber and steel plate are permanently bonded through our special molding and hot vulcanization process. Ceramics will stay in place until completely worn.

Technical Data

Rubber Wear Resistant Ceramic Liner For Conveyro Hopper Bin Techical Data

| Ceramic Tile Specifications | |

| AL2O3(%) | 95±0.5 |

| Bending Strength(Mpa) | >280 |

| Fracture Toughness(MPam1/2) | >3.9 |

| Rockwell Hardness(HRA) | >88 |

| Wear Volume(cm³) | <0.3 |

| Density(g/cm³) | >3.7 |

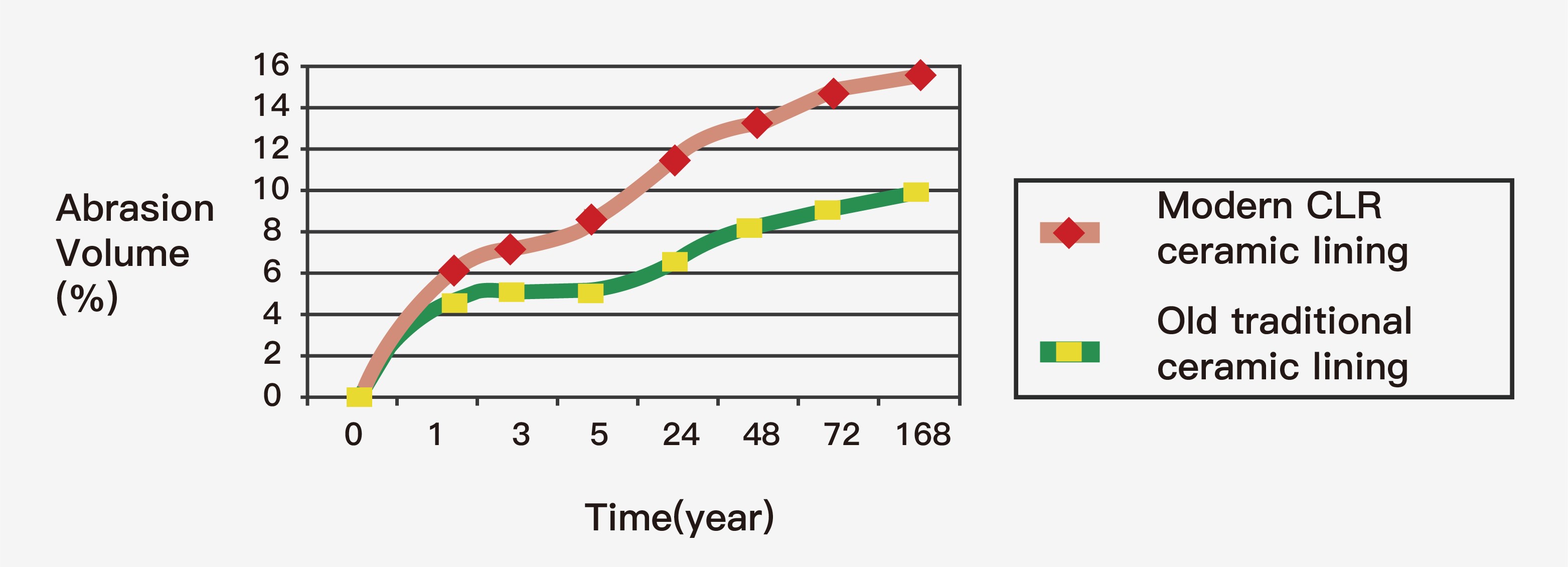

The use of wear-resistant ceramics can greatly save maintenance time and costs, and at least increase the service life of the equipment by more than 10 times.

The use of wear-resistant ceramics can greatly save maintenance time and costs, and at least increase the service life of the equipment by more than 10 times.

| Items | Data |

| Tensile Strength(Mpa) | ≥14 |

| Break Extension(%) | ≥350 |

| Shore Hardness(degree) | 55-65 |

| Break Permanent Deformation(%) | ≤24 |

| Rubber and Ceramic Adhesion Force(Mpa) | ≥3.0 |

| Temperature Resistance(°C) | ≤100 |

Feature Of Ceramic Liner

- High wear-resistant rubber ceramic wear liner is embedding high alumina ceramic into energy absorbing rubber or polyurethane cushion, and bond both to steel backing plate via hot vulcanizing for easy installation.

- Impact absorbing rubber cushions helps reduce impact energy and prevent ceramic tiles breakage.

- CN bonding adhesive backed or Steel backing plate with studs for easy installation.

Product Specifications

| Order No. | Product Name | Dimension(mm) | Ceramic Size(mm) | Rubber Thickness(mm) | Plate Thickness(mm) |

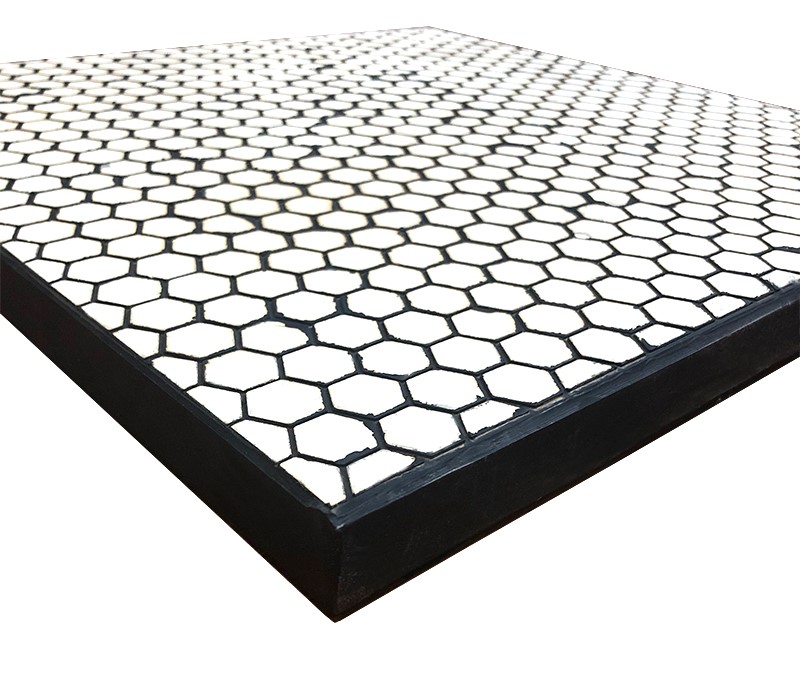

| ZJCER-HW25 | Hexagonal Ceramic Liner | 250*250 | S12*T3 | 10 | 5 |

| ZJCER-HW40 | Hexagonal Ceramic Liner | 400*400 | S16*T3 | 12 | 8 |

| ZJCER-HW50 | Hexagonal Ceramic Liner | 500*500 | S19*T3 | 15 | 10 |

Further Dimensions on Demand

Quality Certifications

Advantage

——Good buffering performance

——Convenient construction

——No sticking and no blocking

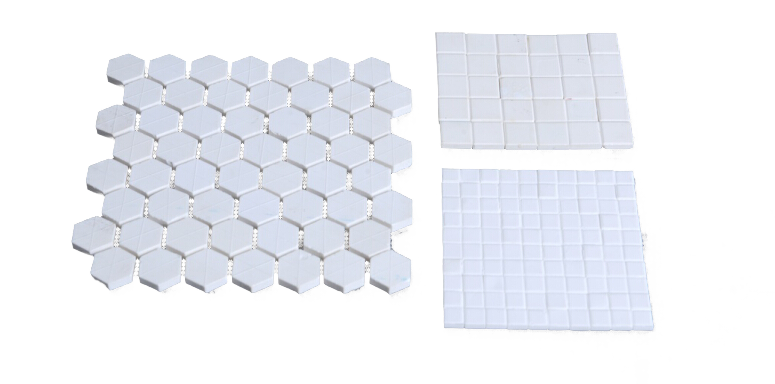

The rubber and ceramic composite wear-resistant products is a customized product, it can be made in various shapes, selected composite material according liner wear of various thicknesses, forming a strong wear layer.

Mosaic: 10x10x2~10mm, 17.5x17.5x2~15mm,20x20x2~15mm,33x33x7~25mm, etc.

Square: 100x100x6~50mm, 150x100X6~50mm, etc.

Hexagonal: S12xT3~20mm, S19xT6~25mm

Spherical tiles: 40x40x40mm, 32x32x22mm, 38x38x38mm, etc.

Cylinder/rod: 6x6mm, 15x15mm, 20x20mm, 31x31mm, 40x40mm, 50x50mm, etc.

The unique toughening formula forms a strong crystal bond, which greatly enhances the impact resistance of alumina ceramics, which is 3 to 5 times that of general standard wear-resistant ceramics.

Parameters

| Brand | BAI-OTT or OEM |

| Main ingredient | Ceramic / Rubber / Steel Plate |

| Model | ZJCER-HW |

| Colour | Black and White |

| Compressive strength | 1200-2500Mpa |

| Liner shape | customised sizes and shapes to suit site chute or silo conditions |

| Bending Strength | >280Mpa |

| Feature | Abrasion and impact resistance |

| Product Construction | Steel plate+Rubber+Ceramic; Rubber+Ceramic; Steel plate+Ceramic |

| Sample | Provide |

| Product Inspection | Available |

| Lead time | Ready to ship in stock |

| MOQ | 20 Sqm |

| Shelf life | 24 Months |

| Supply capacity | 8000 Sqm / Month |

| Certification | ISO9001; ISO14001; ISO45001; CE; UPEM |

| Packing | Pallet, wooden case |

| Delivery Time | 50~100 Sqm, 3-5 days / 200~500 Sqm, 7-10 days |

FAQ

1、How long will your rubber sheets last?

Each conveyor system transports different materials, so the friction coefficient generated can not be determined, you can tell me your requirements and transport materials, we help you to develop a solution.

2、How can I get some samples?

We will finish the samples within 3 days after you confirm our quotation and send us the sample fee. You can ask the courier company to pick up the samples from our company, or you can send us the collect account number of DHL, FedEx or UPS, we can send the samples to you through your account.

3、Can I visit your factory?

Yes, you are welcome to visit our factory anytime, we are near Henan Xinzheng Airport, only 15 minutes drive, we can arrange a car to pick you up.

Related Cases

Product Series

Message feedback

We will arrange an after-sales specialist to contact you as soon as possible to help you find a product or solution that meets your needs and goals.